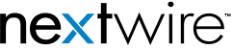

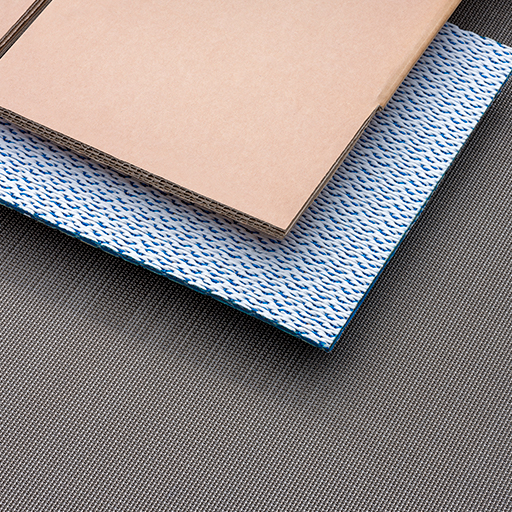

ArmorPress® Single Facer Pressure Belt

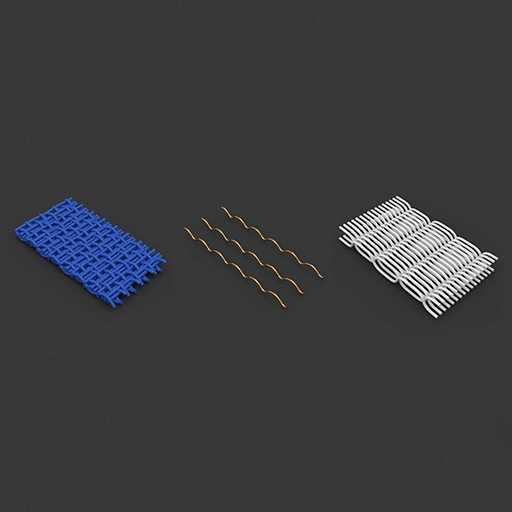

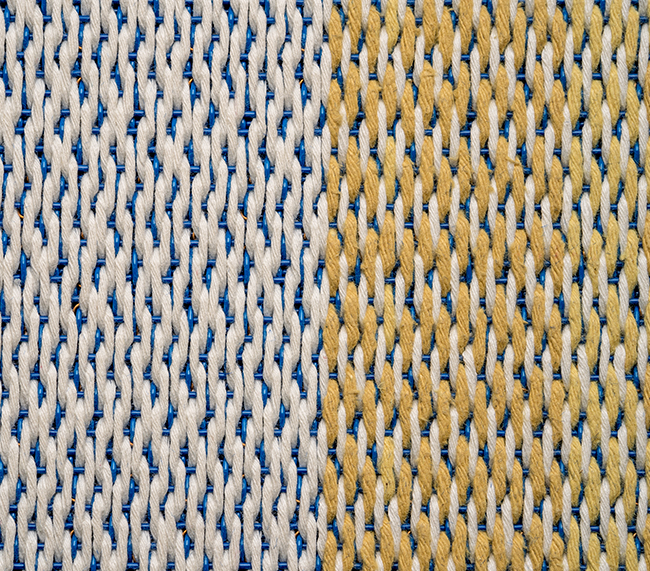

Nextwire® has engineered the next generation belt for the Corrugator Industry. Utilizing innovative ArmorPress® woven metal fabric with optimal wire and mesh configuration, 16% more surface contact is created for an improved bond and heat transfer. ArmorPress® is offered uncoated or with Teflon coating for easy release and increased productivity.

Minimal narrowing and no seam marking combined with longer life contribute to increased production efficiency with numerous reports of belts running in excess of 100 million linear feet. ArmorPress® has a proven track record and is becoming the belt of choice among Corrugator plant engineers.

- Minimal Narrowing

- 16% increase in surface contact

- Frequent runs beyond 100 MLF

- Pre-tested for Tracking

- No seam marking

- Inventory of Stock Sizes Available

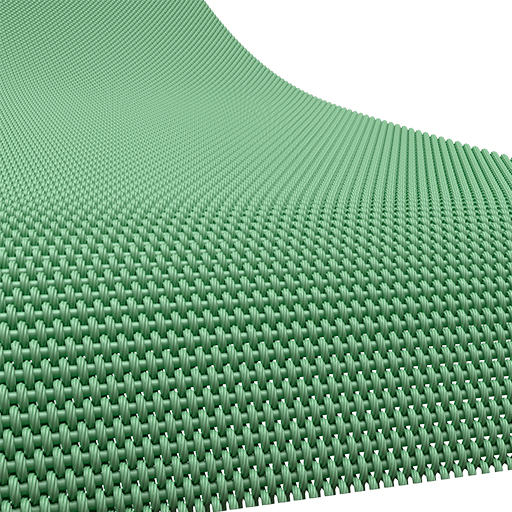

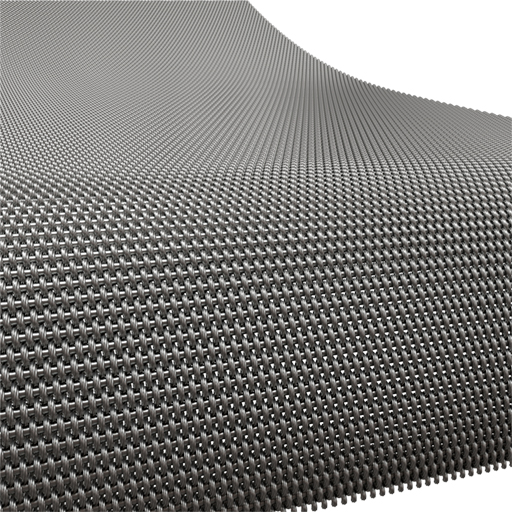

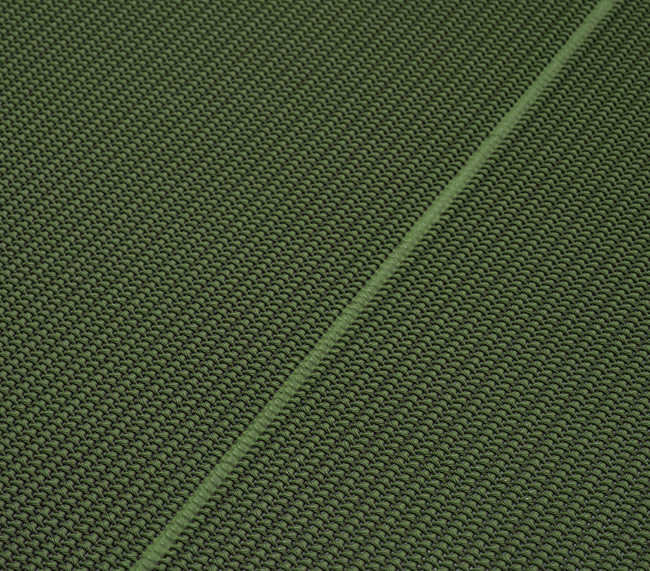

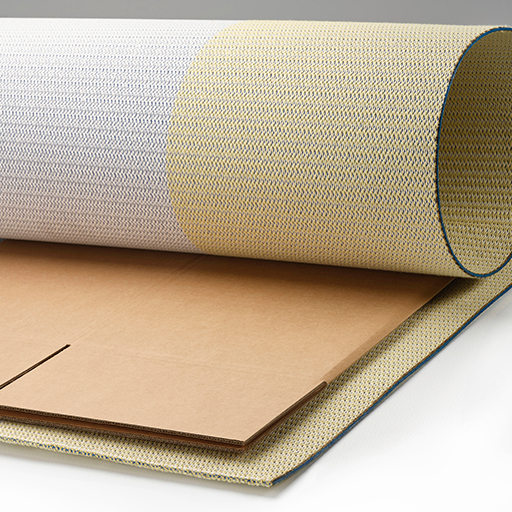

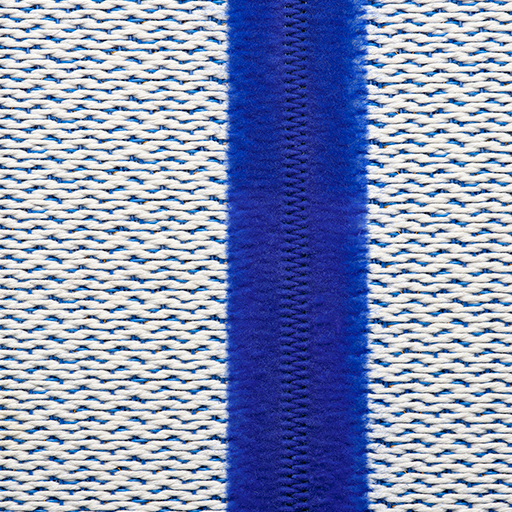

Bluebacker Corrugator Belt

The new generation HybridMesh has an open and robust mesh structure that reduce noise emissions and increases traction features. This is suitable for universal use on double facer machinery. The surface features ensure safe traction of the corrugated board during the whole bonding process. The belt is supplied with a flock seam.

- Excellent flatness and directional stability of corrugated medium

- Consistent belt properties due to heat setting process

- High level of transverse stability and consistent belt running

- Kevlar Edge reinforcement to avoid abrasion wear

- Saving electric drive energy up to 15 to 20 percent

- Reduced glue consumption due to faster evaporation

- Up to 9% less heating energy and about 5% less glue in the drying process

- Significant increase in production speed due to faster drying of the medium

- Standardly electrostatic dissipation and Kevlar edges to avoid abrasion wear on heat plates